The Case Against Wood Energy Efficiency, Tilt Up | November 12, 2015Unfortunately for the wonderfully versatile building material of wood, using it within insulated concrete assemblies is not appropriate.

Concrete bleeds water as it sets up, to consider using non-treated wood in a contained moist location would be disastrous due to the rotting of the wood that would occur.

It has been widely accepted that treated wood is the only application of wood that should be attempted in an insulated concrete assembly.

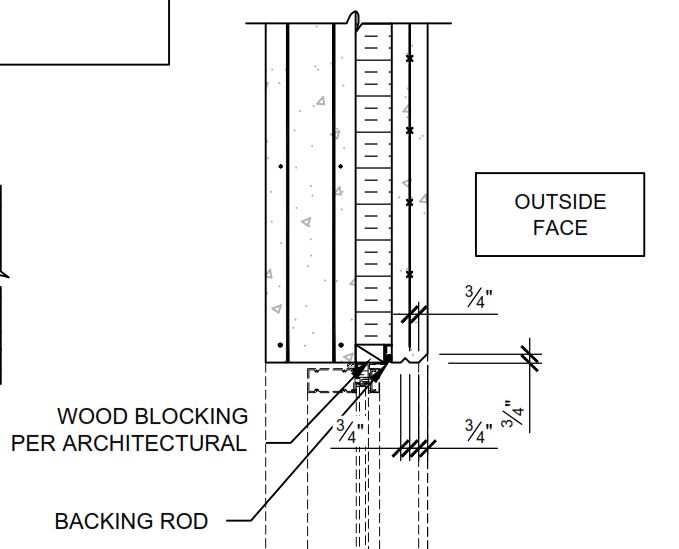

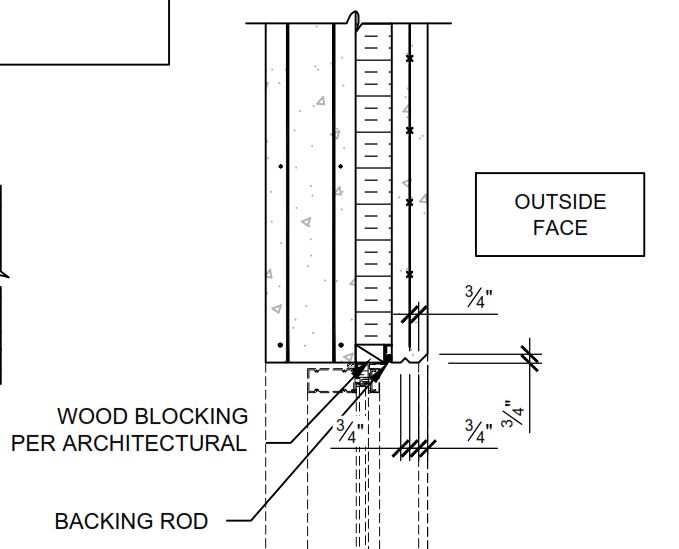

In case you are wondering, treated wood in your insulated concrete assembly would look like this:

What’s wrong with treated wood? If you are thinking we are coming up with reasons why treated wood is not acceptable to sell our thermal break (Tigerloc), you have it backwards. We came up with Tigerloc because we refused to use treated wood in our assemblies to begin with. Treated wood, while having some great uses in wet environments does not belong in insulated concrete assemblies. Here’s some reasons why:

1. Treated wood doesn’t have an insulation value. By using treated wood as per the drawing shown above, your insulation layer is no longer continuous. The ASHRAE code referring to insulated concrete assemblies calls for continuous insulation. By allowing treated wood in your assembly, you don’t have a continuous insulation layer anymore so your project is not in compliance with energy codes. Your customers will not be happy to find out that the new insulated concrete building they have completed is not entirely energy compliant.

2. Treated wood eats aluminum. Read up about it here: http://www.woodpreservation.ca/index.php/en/residential-use/faq under the question: is there any material I can’t use with treated wood?

The skeptics may say that yes there is an issue, it can be avoided with blue skin or proper spacing; however do you want to take the chance in allowing treated wood in your building and compromising your door and window frames?

3. Oh and treated wood eats fasteners too. Kind of like the last point, you have to be very careful that you use the proper fasteners with treated wood otherwise the treated wood will react chemically with the fasteners and destroy them. Again, you can get around this however do you want to potentially have failed frame installation because of using the wrong screws?

As you can see treated wood, while being a versatile and handy construction product does not belong in insulated concrete assemblies. As a supplementary point, when you can consider using other forms of water resistant materials and woods in your projects as treated wood waste is not recyclable and ends up in a landfill. The landfill is also contaminated from treated wood as the chemicals within treated wood bleed into the ground.

The next time you are designing or building an insulated concrete assembly, take a look at your concrete window and door details. If they are showing the window and door linings as being treated wood, consider changing the detail to Tigerloc. Using Tigerloc over treated wood provides a superior insulated concrete product, true compliance with energy codes and no risk of aluminum or fastener failure over time.

Unfortunately for the wonderfully versatile building material of wood, using it within insulated concrete assemblies is not appropriate.

Concrete bleeds water as it sets up, to consider using non-treated wood in a contained moist location would be disastrous due to the rotting of the wood that would occur.

It has been widely accepted that treated wood is the only application of wood that should be attempted in an insulated concrete assembly.

In case you are wondering, treated wood in your insulated concrete assembly would look like this:

What’s wrong with treated wood? If you are thinking we are coming up with reasons why treated wood is not acceptable to sell our thermal break (Tigerloc), you have it backwards. We came up with Tigerloc because we refused to use treated wood in our assemblies to begin with. Treated wood, while having some great uses in wet environments does not belong in insulated concrete assemblies. Here’s some reasons why:

1. Treated wood doesn’t have an insulation value. By using treated wood as per the drawing shown above, your insulation layer is no longer continuous. The ASHRAE code referring to insulated concrete assemblies calls for continuous insulation. By allowing treated wood in your assembly, you don’t have a continuous insulation layer anymore so your project is not in compliance with energy codes. Your customers will not be happy to find out that the new insulated concrete building they have completed is not entirely energy compliant.

2. Treated wood eats aluminum. Read up about it here: http://www.woodpreservation.ca/index.php/en/residential-use/faq under the question: is there any material I can’t use with treated wood?

The skeptics may say that yes there is an issue, it can be avoided with blue skin or proper spacing; however do you want to take the chance in allowing treated wood in your building and compromising your door and window frames?

3. Oh and treated wood eats fasteners too. Kind of like the last point, you have to be very careful that you use the proper fasteners with treated wood otherwise the treated wood will react chemically with the fasteners and destroy them. Again, you can get around this however do you want to potentially have failed frame installation because of using the wrong screws?

As you can see treated wood, while being a versatile and handy construction product does not belong in insulated concrete assemblies. As a supplementary point, when you can consider using other forms of water resistant materials and woods in your projects as treated wood waste is not recyclable and ends up in a landfill. The landfill is also contaminated from treated wood as the chemicals within treated wood bleed into the ground.

The next time you are designing or building an insulated concrete assembly, take a look at your concrete window and door details. If they are showing the window and door linings as being treated wood, consider changing the detail to Tigerloc. Using Tigerloc over treated wood provides a superior insulated concrete product, true compliance with energy codes and no risk of aluminum or fastener failure over time.